Zeller's Story - The making of a plant extract: extraction and filtration

February 27, 2019

Extraction

Extraction is another crucial step in the production of a phyto-pharmaceutical. The choice of parameters such as the extraction solvent and the extraction duration critically determine the final composition of the extract and are decisive for the quality and efficacy of a product.

Depending on the properties of the extraction solvent, different components of the plant will be obtained. More polar solvents such as water can draw out water-soluble components from the plants such as sugars, whereas less polar solvents draw out a different spectrum of components with more non water-soluble substances. The duration of the extraction process, i.e. the time the solvent and the plant material are incubated, can also make a difference to the chemical composition of the extract. This process can be compared with making tea, where changing the time can make a difference to the taste. For example, if the tea is brewed for too long it can lead to the extraction of more bitter components, thus rendering the tea unenjoyable.

Another decisive parameter is the drug-extract ratio (DER). The DER defines the initial amount of drug (technical term for plant raw material) used for the preparation of a certain amount of extract. For an extract with a DER of 10:1 for example, 10 kg of plant raw material is used to produce 1 kg of extract.

Filtration

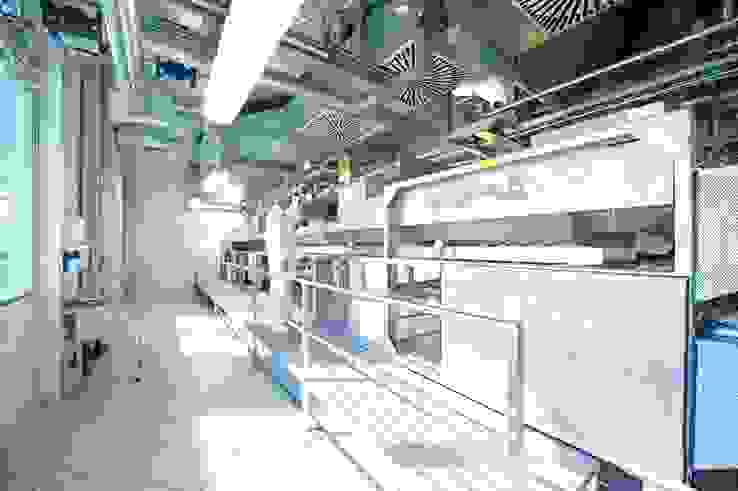

Following extraction, the raw extract containing the solvent with the active ingredients and the remaining solid plant parts need to be filtered in order to separate the solid from the liquid parts. Zeller uses a specialized band filter for this process. Unlike a normal funnel filter, which can be imagined as a coffee filter where the coffee builds up as a filter cake and limits filtration, the band filter allows for highly efficient and homogenous filtering of large amounts of material. Since the solid particles on the band filter are constantly removed, accumulation is prevented and thus, a constant process without the need to change or clean the filter in-between is enabled.

Every step in the production process is carefully optimized and defined via a number of parameters. These are individually adjusted for each Zeller product.

Topics

Filter blog posts by topic by clicking on the tags.