From Seed to Patient

Our commitment to the full control of the value chain allows us to guarantee consistency of the processes resulting in high-quality, safe and effective phyto-pharmaceuticals.

Learn how we get the true benefits of phyto-pharmaceuticals by controlling the seed to patient chain in the video above.

FROM SEED TO PATIENT

Our philosophy for producing high-quality phyto-pharmaceuticals is sophisticated: consistent quality and efficacy can only be achieved by starting from the very beginning of the process with the seed of a carefully selected plant. Agro expertise means having detailed knowledge about each plant – its source, benefits, quality and consistency. This is followed by comprehensive optimized procedures for cultivation, collection, extraction and further production steps and leads to clinical studies to prove efficacy and safety of each product. Each step of this seed to patient process is verified by analytical controls.

QUALITY FIRST

Our commitment starts with the screening of plant varieties and selection of an elite plant – this stage is crucial for the development of the extract and the quality of the finished product. Ensuring that all processes are according to GACP and sourcing the highest quality ingredients allow us to develop a portfolio of premium phyto-pharmaceuticals based on unique herbal extracts.

BATCH-TO-BATCH CONSISTENCY

We follow strict processes to control each stage of production. This carefully considered approach allows for batch-to-batch consistency, which means that the medical product tested in clinical trials has the same batch composition and thus clinical effect as the finished products.

EXPERTISE

The commitment, experience and creativity of our employees are the source of our success. Driven by clinical evidence and applying a quality-first approach to the development of our medicines, millions of people in Switzerland and around the world enjoy the health benefits of Zeller products.

Screening and Selection

Screening, selection and breeding of elite plant varieties is based on pharmacological and phytochemical criteria to find the optimal plant for medical use.

Controlled Cultivation

Standardized, controlled cultivation and harvesting under Good Agricultural and Collection Practice (GACP) ensures consistent plant raw materials for high-quality phyto-pharmaceuticals.

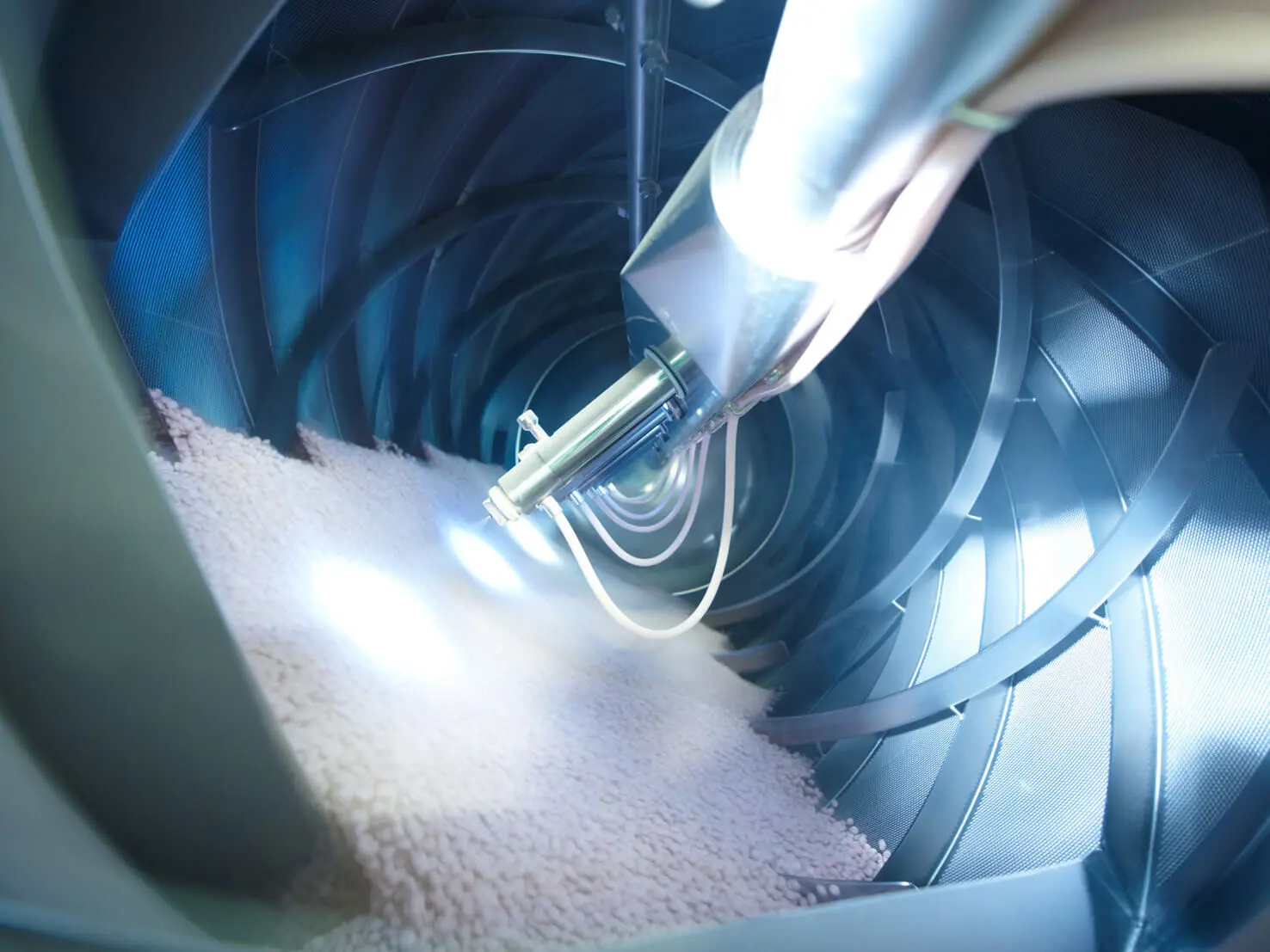

Extraction

Dried and milled plants are extracted using state-of-the-art techniques to guarantee the optimal ingredient sprectrum from each plant.

Tableting & Packaging

Quality controls are performed at each step of the production process to ensure batch-to-batch consistency to maintain the highest quality standards of our phyto-pharmaceuticals.

Clinical Studies

The results of our clinical trials have been published in numerous international peer-reviewed scientific journals. Our products are non-inferior to chemical synthetic drugs and are the preferred choice in first-line treatment amoung healthcare professionals.

Approved medicine

Our phyto-pharmaceuticals have OTC status in a number of markets thanks to the quality of our EU-CTD dossiers. Their excellent safety profile makes them suitable for long-term therapy.